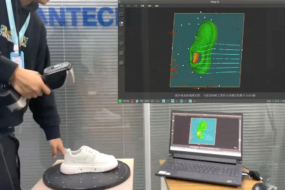

Hangzhou, China, April 9th, 2024 — Leading the forefront in 3D measurement technology, Scantech is thrilled to unveil its latest innovation: optical automated 3D measurement system AM-CELL C. This cutting-edge system, designed for the automated inspection of small to medium-sized parts across various industries, is a game-changer for manufacturers looking to boost their production efficiency.

At its core, the AM-CELL C system is a synergy of precision engineering and technology, featuring a robot unit, a positioner unit, and a TrackStation Unit. Its modular design is a standout, offering unparalleled flexibility in layout and deployment for multiple-positioner operations. This adaptability makes it a perfect fit for a wide range of manufacturing environments, from stamping and injection molding to machined sheet metal and cast parts production.

Scantech’s commitment to innovation is further demonstrated through the integration of its newly enhanced software, DefinSight-AM. This powerful software complements the AM-CELL C system, facilitating seamless operations across various production settings and marking a significant step forward in intelligent manufacturing.

Key Features of the AM-CELL C System

Innovative Modular Design: Tailored to meet the diverse needs of the industry, the system’s flexible layout options simplify batch inspections, ensuring a quick setup and reducing operational complexities.

Precision and Efficiency: Equipped with a special architecture that combines both robot and system controllers, the AM-CELL C offers precise control, high sensitivity, and intelligent motion systems for reliable, efficient operations.

Metrology-Grade Measurement: Compatible with Scantech’s comprehensive range of 3D measurement solutions, the system guarantees high-precision, automatic inspections around the clock, with an impressive measurement rate and accuracy.

Flexible Deployment: Designed for versatility, the system supports various configurations to meet specific production needs, significantly reducing cycle times and enhancing overall efficiency.

Safety and Reliability: Advanced servo-mechanisms and various protective measures ensure the safety of human operators, allowing for a shared workspace without compromising operational security.

The AM-CELL C series is not just a testament to Scantech’s engineering excellence but also a reflection of our deep understanding of the industry’s evolving needs. Its compatibility with a wide array of robots and intelligent turntables offers a scalable solution to meet the demands of different parts and production scales.

Furthermore, the DefinSight-AM software, with its advanced data capturing and robot control capabilities, streamlines the measurement process, reducing the skill level required for operation and ensuring reliable, precise results. This software is a cornerstone of the AM-CELL C system, facilitating efficient, lights-out factory operations and ushering in a new era of unmanned production environments.

Scantech’s latest offering is set to redefine industry standards, providing manufacturers with a robust tool for enhancing productivity, reducing costs, and standardizing quality control processes. With applications ranging from shop floor measurements to educational settings, the AM-CELL C series is poised to deliver unparalleled experiences and solidify Scantech’s position as a leader in 3D measurement solutions.

About Scantech

Located in Hangzhou, China, SCANTECH (HANGZHOU) CO., LTD. is a global innovator in 3D technology. Our expertise spans the research, development, production, and sales of 3D scanners and systems. We pride ourselves on our extensive portfolio of industrial high-precision and professional cost-effective 3D scanners, including portable, tracking, automated industrial systems, and professional color 3D scanners. Our commitment to excellence drives us to continually explore new horizons in 3D technology, striving to offer our clients the most advanced and reliable solutions in the market.