The integration of 3D scanning and 3D printing technologies is revolutionizing multiple sectors, including product design, manufacturing, art, and various aspects of daily life. This synergy forms a seamless process that greatly enhances cultural relics and archaeology, medical rehabilitation, custom art creation, and even personalized consumer products, thereby unlocking new possibilities for product designers, engineers, manufacturers, artists, and medical professionals. By enabling the direct and efficient transformation of digital models into physical objects, these technologies are not only streamlining development processes but also fostering innovation across industries.

What is 3D Scanning?

3D scanning captures the geometric shape and external features of objects using technologies like laser, optical, or other sensors, converting them into digital 3D models. Sensors collect data points from the object’s surface to generate or reconstruct its three-dimensional model. This technology is applied in various fields such as industrial design, manufacturing, cultural heritage preservation, the medical field, additive manufacturing, virtual reality, and reverse engineering. It allows for the rapid and accurate acquisition of three-dimensional object information, providing critical data for design, analysis, and manufacturing processes.

What is 3D Printing?

3D printing, or additive manufacturing, creates three-dimensional objects by depositing material layer by layer, following a digital model. This process uses various materials, including plastic, metal, ceramic, and composites. It contrasts with traditional subtractive manufacturing, which removes material from a solid block. 3D printing allows for complex geometries and customized designs, reducing costs and lead times.

Case Study: 3D Scan For 3D Printing

Cultural Heritage Preservation

3D printing technology is advancing rapidly, presenting new opportunities in cultural heritage preservation. It enables the accurate replication of valuable artifacts, making them accessible worldwide and enhancing the appreciation of history and culture. This technology is essential for object reconstruction, research, documentation, protection, and education.

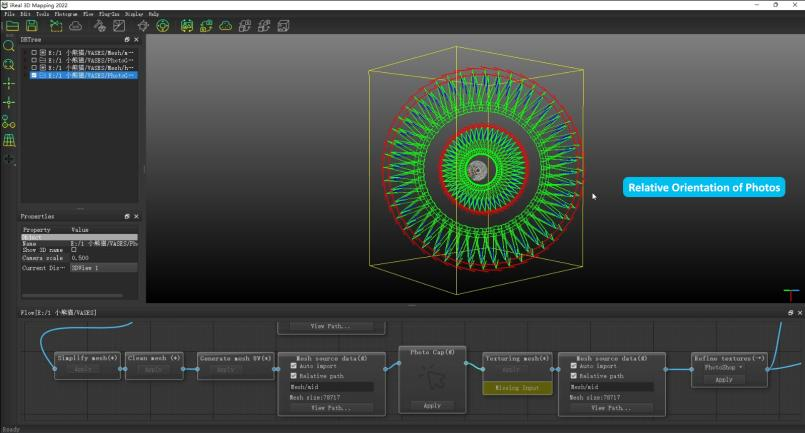

Using iReal 3D Mapping software, we accurately capture a vase’s 3D data and images, overcoming challenges such as faculae and uneven shading due to its reflective surface. Sailner 3D’s full-color printing technology then transforms this model into a physical replica, exemplifying replication accuracy.

iReal M3 3D Scanning

Taking Groups of Images

Creating Textures for the 3D Model in iReal 3D Mapping Software

Post Process After Color 3D Printing

Art and Design

3D technologies unlock immense creative potential. Scanning captures detailed models of real objects and human figures, while 3D printing offers unprecedented design freedom, enabling the creation of complex shapes and concepts. This combination accelerates the realization of innovative ideas, pushing the boundaries of creativity.

3D Printed Mask

Wearing the Customized Mask

Consider the creation of a personalized art mask. It begins with the iReal M3 3D scanner capturing facial dimensions. Engineers then refine the mask using Blender for shaping and Mari for texturing. The Bambu Lab X1 Color 3D Printer brings the design to physical form, crafting a tangible piece of art.

iReal M3 Face 3D Scanning

Design the Art Mask in Blender

Adding Textures in Mari

Bambu Lab X1 3D Printer

Cultural Creative Products

Traditional exhibition constraints and the fragility of artifacts have limited museums’ ability to present history and culture. Now, technological advancements are enabling more engaging and immersive exhibition experiences.

3D scanning allows museums to capture detailed information about cultural objects safely, supporting dynamic online exhibitions. Combined with 3D printing, museums can create novel, interactive products for visitors.

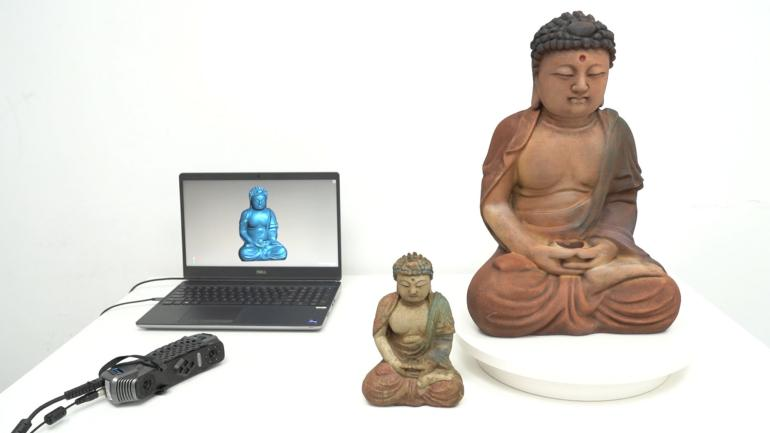

For example, after scanning a Buddha statue using the SIMSCAN 3D laser scanner, we employed a sand mold 3D printer from Kocel Steel Foundry Co., LTD to produce a physical replica, showcasing the practical application of these technologies in cultural dissemination.

SIMSCAN 3D Scanning

3D Scanned Data

Sand Mold 3D Printer

Post Processing After Sand 3D Printing

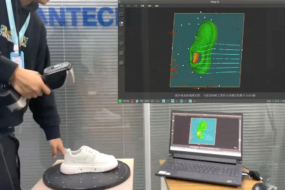

Customization

iReal 3D scanners excel in digitizing human bodies and body parts, offering precise data for customization in healthcare and sports, particularly for athletes. Tailored equipment can be crafted to match athletes’ requirements, enhancing comfort and maximizing performance improvements. The collaboration between our reseller in Italy, 3DItaly, and Reggina 1914, aimed to provide personalized, lightweight protective gear for promising young footballer Niccolò Pierozzi.

Make A 3D-Printed Nose Mask and Shin Guards for the Footballer

Our collaboration with our Italian reseller, 3DItaly, and the football club Reggina 1914, focused on developing personalized, lightweight protective gear for the young football talent, Niccolò Pierozzi.

Young Footballer Niccolò Pierozzi

Achieving the Perfect Fit and Lightweight Design:

- Full Body Scanning: The iReal 2E 3D scanneris used to perform comprehensive body scans, capturing detailed data of the face and legs.

iReal 2E Human Body 3D Scanning

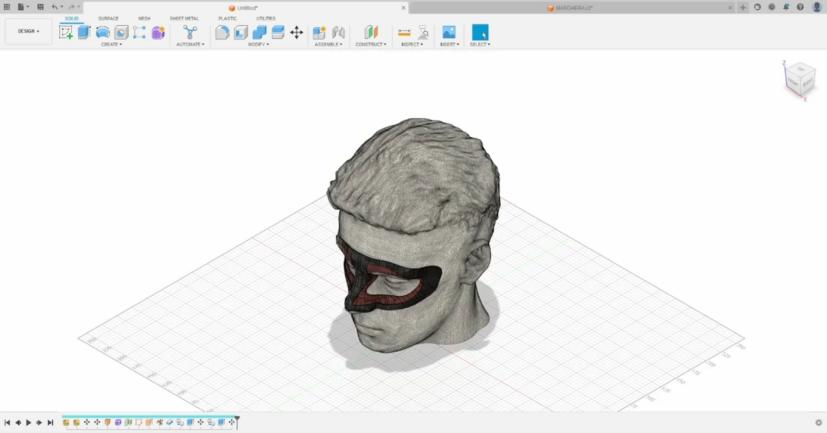

- Design: Utilizing Fusion 360 software, we design the mask and shin guards based on the accurate 3D scans.

Design in the Fusion 360 Software

- 3D Printing: These designs are brought to life through 3D printing, ensuring the protective gear precisely fits the athlete’s specifications.

These cases underscore the transformative impact of 3D scanning and printing across various sectors. 3D scanning and printing technologies are not just innovating; they are reshaping the future by offering tailored solutions that were once thought impossible.

Interested in learning more about iReal 3D scanners or our digital solutions? Contact us to book a demo and receive a complimentary consultation.